How Do You Quantify the Value of Electrifying Your Fleet?

Electric vehicles have been established as the future of commercial fleets, with more options being put on the market every year and big companies making the switch. Between the opportunity to cut maintenance costs, reduce your carbon footprint and the ability to collect real-time data through fleet-wide telematics systems, integrating EVs into your fleet is a no-brainer. However, the change from traditional gas and diesel vehicles involves many considerations, along with major acquisition costs.

The price to pay

Upfront costs of going electric can be a major deterrent for utilities companies, as they include not only the price of the vehicle, but the installation of charging infrastructure. Prices of Class 4-6 trucks can average between $100,000 and $200,000, with Class 8 trucks costing upwards of $300,000 –nearly double the price of medium- and heavy-duty diesel trucks. Additionally, the initial investment price of installing charging stations could be scaring away companies considering going electric.

One thought that immediately comes to mind when this topic comes to the forefront of discussion, is that I don’t think there’s anything that is creating a hurdle in implementing EVs into the utilities industry, other than the installation of charging infrastructure. Once everything is in place it will work fairly well and prove itself valuable.

Other variables to consider in acquisition costs include battery costs and replacement, as well as system and software upgrades down the line.

Quantifying the benefits

As with any major investment, the initial and ongoing costs must be weighed carefully against their ultimate value to figure out total cost of ownership. However, the metrics by which this value is measured must be clearly determined – if not, any value provided is subjective and non-quantifiable. So, how do we calculate this elusive figure called ROI?

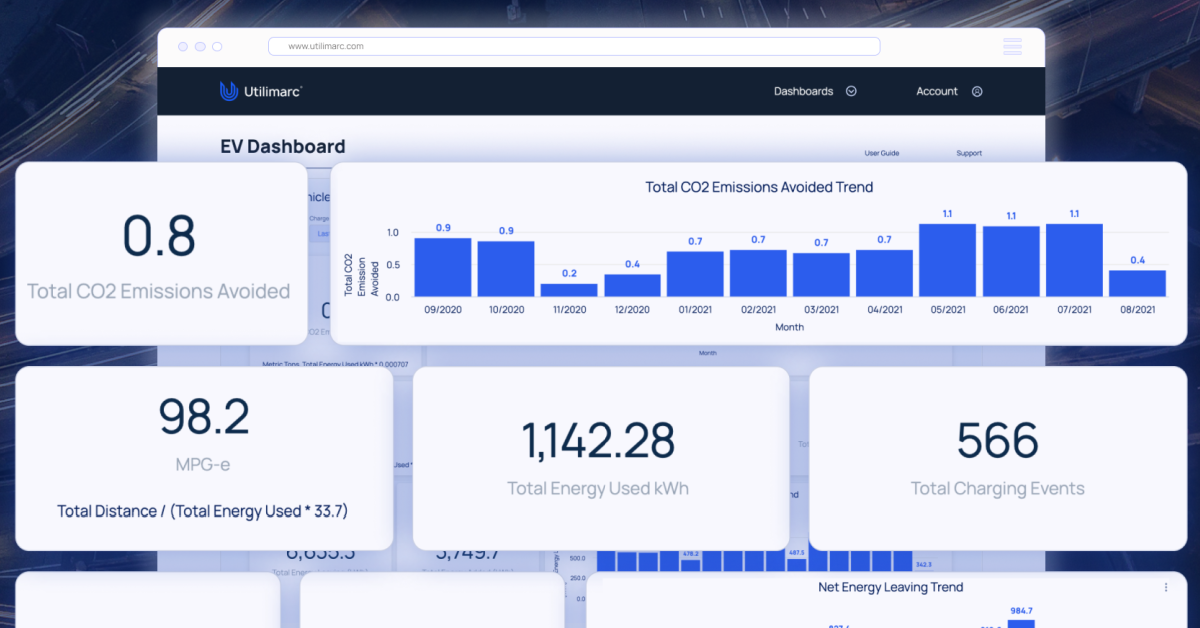

In search of some solid answers, we surveyed 200 of our largest customers to see how major fleets would be measuring return on investment. According to our results, the three most important metrics for measuring the value and performance of EVs were fuel savings, reduction of CO2 emissions and the reduction of maintenance costs.

Fuel Savings

Overall, EVs are far more energy efficient than gas or diesel vehicles. Over 75 percent of an EV’s energy is converted into motion, whereas only 35 to 45 percent of liquid fuel is converted to motion. Electricity is also a much cheaper energy source than diesel. While diesel across the United States averages around $2.96 per gallon, according to the EIA, electricity prices average only $1.29 per gallon of diesel equivalent. According to one report, a single Class 6 electric truck that runs 25,000 miles per year can save upwards of $40,000 in its 10-year lifetime.

CO2 Emissions

According to the Environmental Protection Agency, diesel Class 4-7 trucks can emit up to 8 grams of NOx per mile traveled, contributing to over one-fifth of the United States’ global warming pollution. With zero-emission EVs, however, it’s no surprise that governments are offering tax breaks, grants and incentives for making the switch from fuel to electric.

Maintenance Costs

With far less moving parts to an electric vehicle, the cost of maintenance and repairs is significantly less when compared to its diesel and gas counterparts. Off the bat, electric vehicles have no need for regular oil changes, diesel emission fluid replacement, or regular maintenance of parts like fuel injectors, carburetors, belts and transmissions. It’s estimated that a Class 8 electric truck will costs nearly 5 cents per mile less to maintain than a diesel vehicle, resulting in hundreds of thousands of dollars in savings over the vehicle’s lifetime.

Other factors to consider

While companies with a need for heavy-duty trucks might be hesitant due to a current lack of options on the market, companies with mostly medium-duty vehicles are in the optimal position to integrate electric vehicles into their fleets.

Right now, the best application for electric vehicles are the last-mile organizations, the folks that are doing deliveries like Amazon or US Postal Service. The reason for this being that they are optimizing the range of the vehicle. They’re all centrally located so that you can go back to a hub and get charged, as well as a lot of stopping involved that allows you to regenerate the battery. You also generally know how far you’re going to travel which eliminates the question of range anxiety.

Another factor to consider is the weather in which you’re operating. As lower temperatures can gravely affect battery life, this will potentially lead to more frequent battery replacement and greater overall expenses.

Return on investment for electric vehicles will ultimately vary based on vehicle classes in a fleet, vehicle uses and charging schedules. However, the lifetime savings in operating an EV will offset the higher upfront costs in the end. It’s just a matter of making the initial investment.

If you’re interested in learning more about electric vehicles and how they could potentially work for your fleet, schedule a demo with a member of our analytics team.

Paul Milner

Benchmarking and Professional Services Manager

Paul Milner is a Benchmarking and Professional Services Manager at Utilimarc. He studied mathematics and philosophy at the University of St. Thomas in Minnesota. Working at Utilimarc for nearly ten years, he helps find the stories and solve problems within complex data sets. See more from Paul